Choosing Finishing Options for Sheet Metal Parts

Title: Choosing Finishing Options for Sheet Metal Parts: Benefits and Considerations

When it comes to finishing sheet metal parts, your choices depend on your specific needs. Whether you're aiming for aesthetics, durability in challenging environments, or testing overall functionality, understanding your goals guides your finishing requirements. Let's explore some options.

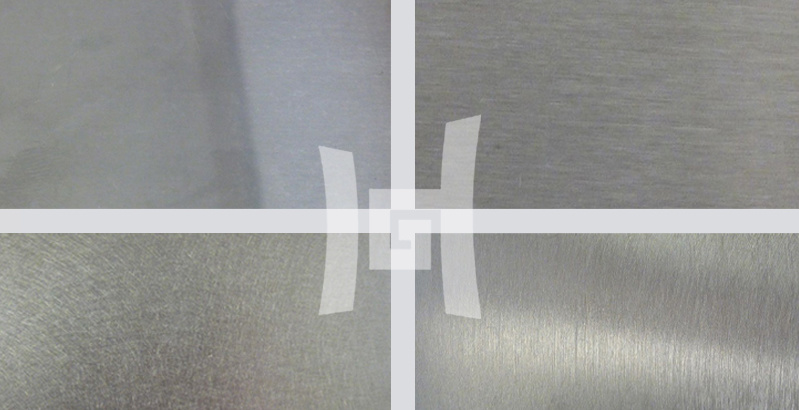

Standard Surface Finishes:

If your priority is testing form, fit, or function without emphasizing appearance, deburring is crucial. This process removes sharp edges and raw finishes resulting from laser cutting. It's noteworthy that we deburr all parts as part of our standard offering for free. This not only smooths edges but also enhances safety. Additional finishing options include:

Long-life Finishes:

Plating: Used to strengthen and prevent corrosion by adding a thin layer of metal like chromate or zinc. Particularly useful for aluminum parts and during field testing.

We offer pre-plated steels like galvanized and galvanneal, providing a low-cost alternative.

Teda offers plating options such as anodizing, block oxide, chromate, tin, and zinc.

Passivation: A cleaning process for stainless steel parts that limits corrosion and rust by removing contamination traces. Recommended for stainless steel parts facing extreme conditions.

Cosmetic Finishes:

For production-grade parts used in end-use products or customer-facing components, consider:

Powder Coating: Creates a tough finish tougher than traditional paint, offering a textured or non-textured color finish in over 50 colors. Provides protection against scratches, chipping, and corrosion.

Silk Screening: Ideal for applying design elements like logos and labels directly onto parts. Teda's service allows custom coloring closely matching Pantone numbers.

These cosmetic finishing options are well-suited for faceplates, signs, panels, and customer-facing enclosures.

Understanding your goals and the intended application of the part helps in choosing the right finishing option. Whether it's enhancing functionality, ensuring longevity, or meeting aesthetic requirements, the finishing choices outlined above cater to a range of needs.

Metal Coils Dealer Teda In China

We cater to global markets, including Africa, America, Asia, Europe, the European Union, and the Middle East.

Contact us today to request a free estimate or send an enquiry on : sales1@tedaganghua.com

Whatsapp: +86 15822676888

评论

发表评论