Unveiling the Intricacies of Galvanized Coil Production

Unveiling the Intricacies of Galvanized Coil Production: A Comprehensive Insight

In the realm of manufacturing and construction, galvanized coils are indispensable components renowned for their durability, versatility, and corrosion resistance. The production process behind these coils is a testament to precision engineering and innovation. In this blog post, we vill embark on a journey to uncover the intricacies of galvanized coil production, exploring the methods, materials, and benefits that make them a cornerstone of modern industry.

Understanding Galvanized Coils

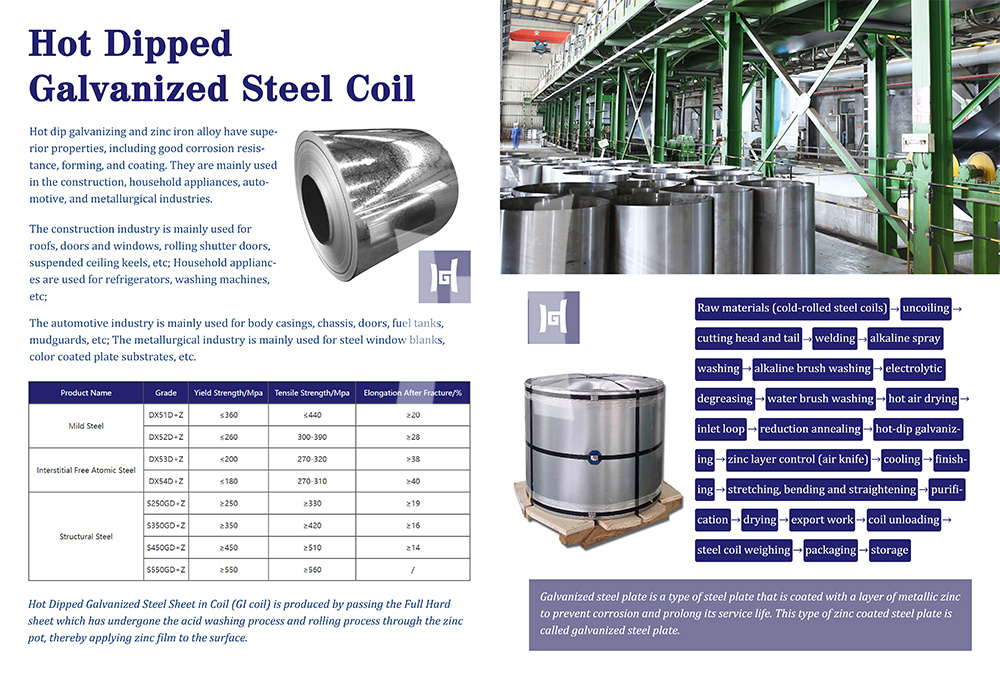

Galvanized coils are steel sheets or strips that undergo a hot-dip galvanizing process, where they are immersed in a bath of molten zinc. This process creates a protective zinc coating on the steel surface, shielding it from corrosion, rust, and environmental damage. The result is a robust and long-lasting material capable of withstanding the rigors of various applications.

The Production Process

1. Preparation of Steel Substrate:

The production journey begins with the selection of high-quality steel coils, which are cleaned to remove any surface contaminants, oils, or impurities. This ensures optimal adhesion and uniform coating during the galvanizing process.

2. Galvanizing Bath:

Once cleaned, the steel coils are immersed in a bath of molten zinc at temperatures exceeding 450°C (842°F). The zinc reacts with the steel surface, forming a series of zinc-iron alloy layers that provide superior corrosion protection.

3. Cooling and Solidification:

After galvanizing, the coated steel coils are cooled in a controlled environment to facilitate solidification and adherence of the zinc coating. This step ensures uniform coverage and optimal adhesion, enhancing the durability and longevity of the galvanized coils.

4. Surface Treatment:

Upon cooling, the galvanized coils may undergo additional surface treatments, such as passivation or oiling, to further enhance corrosion resistance and improve handling properties.

Advantages of Galvanized Coils

The production of galvanized coils offers a multitude of advantages:

1. Corrosion Resistance:

The zinc coating provides unparalleled protection against corrosion, rust, and environmental degradation, extending the lifespan of the steel substrate.

2. Durability:

Galvanized coils are highly durable and resistant to mechanical damage, abrasion, and wear, making them suitable for a wide range of applications.

3. Versatility:

Galvanized coils find applications across various industries, including construction, automotive manufacturing, agriculture, and more, owing to their versatility and adaptability.

4. Sustainability:

Galvanizing is a sustainable process that minimizes waste and energy consumption, making it an environmentally friendly choice for eco-conscious manufacturers and consumers.

Conclusion

In conclusion, the production of galvanized coils is a testament to the ingenuity and precision of modern manufacturing processes. From steel substrate preparation to hot-dip galvanizing and surface treatment, each step is meticulously executed to produce a superior-quality product that meets the stringent demands of modern industry. With their unmatched durability, corrosion resistance, and versatility, galvanized coils continue to be a cornerstone of construction, manufacturing, and infrastructure projects worldwide, ensuring longevity, reliability, and sustainability for generations to come.

Metal Dealer Teda In China

We cater to global markets, including Africa, America, Asia, Europe, the European Union, and the Middle East.

Contact us today to request a free estimate or send an enquiry on : sales1@tedaganghua.com

Whatsapp: +86 15822676888

评论

发表评论